- Home

- Products & Applications

- Supervisory System

- Build Or Buy?

- Pulsed Combustion

- Tunnel Kilns

- Periodic Kiln Construction

- Firing Curves

- Screen shots

- Ram Control

- How To Order

- Version History

- Downloads

- Kiltel Tech Notes

- Kiltel Program Files

(password required) - Customers

- Compatible Suppliers

- Contact Kiltel

Kiltel tunnel kiln supervisory system (1 of 4) installed at Pine Hall Brick in Madison, NC. Existing loop controllers were replaced with new Yokogawa UT350s. The new systems were brought on-line while the kilns were running, with no interruptions.

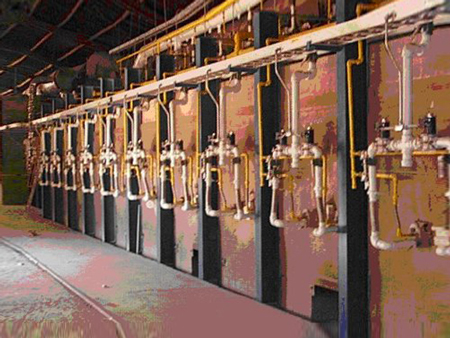

Kiltel pulsed combustion retrofit at Hanson Brick Co., Athens, TX. Existing NA Tempest burners were completely re-plumbed with pulsing components. New air and gas manifolds were installed, and the kiln exterior was sealed with Gunite. Kiltel has also installed supervisory control systems with pulsed combustion re-fits at Hanson plants in Mineral Wells, TX and Mooringsport, LA.

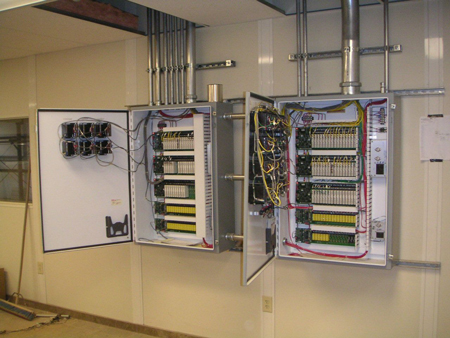

Kiltel data panels at Pine Hall Brick in Fairield, GA. Kiltel provided the supervisory system for this new 400' pulsed-combustion tunnel kiln and dryers, designed and constructed by Harrop.

Kiltel data panels at Pine Hall Brick in Fairield, GA. Kiltel provided the supervisory system for this new 400' pulsed-combustion tunnel kiln and dryers, designed and constructed by Harrop. This view shows the 26 Yokogawa loop controllers. The Kiltel system is also integrated with multiple Allen-Bradley CompactLogix PLCs on the stack scrubber and car-moving systems.

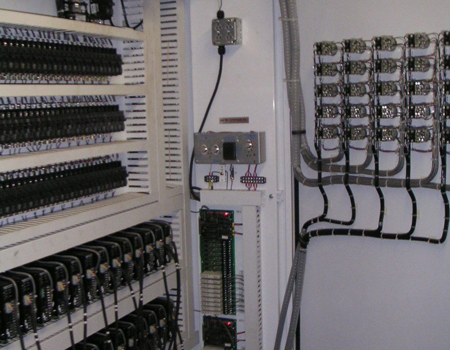

This set of Allen-Bradley Powerflex VFDs are fully integrated in this brick plant's Kiltel supervisory control system. The daisy-chained communications cable is visible below the units.

This is one of 16 Kiltel panels which control multiple VFD devices used to deliver sawdust to sets of ports along the top of a brick plant tunnel kiln; the main VFD panels were built by Harrop. The Kiltel supervisory system allows precise metering of solid fuel into multiple locations in each of the kiln's combustion zones, with adjustable offsets for each delivery position so that overall energy uniformity can be maintained.