Kiltel's supervisory process control system provides data acquisition and control functions for continuous and periodic heat-treating processes. Although most of our experience is in the ceramics industry (brick, whiteware, tile, refractories, specialty ceramics) and steelmaking, our technology can easily and directly be applied to any sort of heat-treating process, including metallurgy, food processing, wood drying, and similar applications. Process venues are thus described as "kilns", but the control technology is equally applicable to furnaces, ovens, lehrs, boilers, etc.

The Kiltel host computer is meant to be wholly dedicated to running the Kiltel program and monitoring/controlling the operations of up to 24 kilns, and is typically not shared with other programs or tasks, although the Windows operating system's multitasking capabilities do allow the computer to simultaneously perform other activities. The computer must be installed in the protected (ie, dry, relatively dust-free, air-conditioned) environment of a control room or in a protective enclosure on the factory floor if no control room is available.

In addition to the computer and software program, Kiltel manufactures data acquisition panels consisting of signal interface boards and data modules. These panels are typically mounted in a NEMA enclosure, located either in the control room or on the factory floor near to the process. Process wiring is brought into this interface box and distributed among the various input terminals so that the computer may read the process signals. The signal interface electronics enclosure must be maintained at less than 110F, which may require cooling or air conditioning.

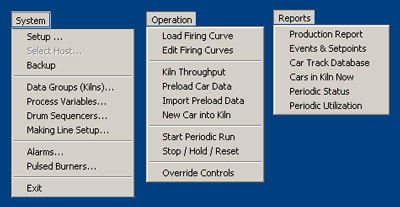

The KILTEL program is a native Windows application, and follows closely the design guidelines for the Windows user interface. The program is highly graphic, featuring the ability to easily create pictorial views of kilns, plans, layouts, instruments and so forth, which can then be decorated with dynamically-updated numeric value and status displays.

Each view of a process occupies the entire screen, and is given a tab entry along the top of the screen beneath the main menu. Clicking on any display group tab resets the screen to that view. Each process view is analogous to the Windows Desktop, in that it can have as background either a plain color field, or any object which can be represented in standard BMP format -- a digital photo, an AutoCAD drawing, a schematic drawing created in MSPaint or any other drawing package, and so forth. The Windows Desktop also typically has icons representing actionable objects such as programs and files, and, to continue the analogy, each Kiltel screen can be decorated with display panels showing dynamic PV values and kiln status. The PV panels can be shown in several sizes, with different amounts of information. The combination of relocatable PV panels together with unlimited graphic representations provides a powerful management information tool for immediately capturing and presenting complex process status, and one can easily and quickly construct highly detailed display screens. Screens may be added, deleted or modified at any time as a simple drag-and-drop setup exercise, without requiring any programming; the program does not impose limits (or cost charges) on the number of display groups or PVs displayed, so these items may be configured (by the customer) to suit each installation.

The Kiltel program runs full-time, constantly gathering process data that is added to the master database. Data gathering is highly multi-threaded and occurs at all times while the program is running, and is not affected by user actions or any "foreground" program activity, whether reviewing current data or exploring historical data. This means that any available option may be explored/exercised at any time, without interrupting the vital functions of data acquisition and process management, which are carried out in separate threads within the program.

The program conducts continuous measurement of all Process Variables (PVs). The overall cycle time for a "sweep" of all variables is typically less than 10 seconds, meaning that any "snapshot" set of values will be contemporaneous to within this time, referred to as the data latency of the system. Current values for each PV are reported as they are acquired to the screen displays and elsewhere, and are accumulated in running short-term averages.

Data is saved to disk at 2-minute intervals, comprising 720 points per day for each PV. The data that is saved is the PV average value (accumulated sum divided by number of measurements since last save). A data file is created for each day, covering times from 00:00 through 23:59. When midnight passes, the next write operation creates a new data file, fully blocked out for the anticipated 720 daily data sets.

Data files are opened momentarily for each data writing operation and are immediately closed thereafter. Opening/closing the files for each write provides an extra measure of data security, since files which are in an open condition during a computer power failure may be left in an unrecoverable state. Data present in memory and not written to file is lost when system power fails, but the low data writing latency ensures that this is at most two minutes' worth of data, a single point.

This form of files organization is also well suited for use in networked environments where the process data gathered by one computer can be accessed in real-time by other computers on the network without disturbing the on-going process control application. The Kiltel program includes a "thick client" version that is easily installed on other networked computers, so that managers and engineers can instantly view both current real-time kiln status as well as historical performance from their offices, home computers (or iPhones).

A detailed record of current operational status (active firing curves, display groups and other parameters) is always maintained up-to-date. When the system automatically re-activates following a power outage or other interruption, this information allows immediate and smooth resumption of prior activities, with data loss and supervisory control loss limited strictly to the duration of the system downtime, and without requiring operator actions.

The program's organization has been developed to closely track actual manufacturing tasks, and is designed to be immediately useable by plant personnel without requiring special terminology, computer expertise or programming of any kind.