Quotations for Kiltel supervisory systems are based on the detailed physical attributes of your kilns and their current and future instrumentation. Each Kiltel system will include one or more host computers, together with data i/o panels built by us to match the needs of the installation; system quotes typically also include loop controllers and sensors as required. Systems are provided on a complete turn-key basis including all hardware, installation, verification and training, and it is our practice to provide firm fixed-price quotes so that our customers can place an order with confidence that the system will be delivered on-time and on-budget, will be installed quickly with minimal or no process interruptions, and will immediately be fully functional. Kiltel systems always include full access to all Kiltel's software features and hardware support; there are never hidden post-sale implementation charges of any kind.

Project quotes will include Kiltel software, computer(s), installation and warranty support, plus the data acquisition and control components required for the particular installation. Supplied hardware is closely matched to actual system needs, so that entry costs are not inflated by over-capacity or unused items. Once installed, the hardware complement of any Kiltel system can easily be enlarged to accommodate additional data channels and even entire additional kilns, and system expansion costs for existing Kiltel sites are priced on a hardware-only basis. Kiltel will be glad to schedule a plant visit to inspect your kilns, answer questions about our supervisory system, and address your engineering concerns. In order to prepare a quote for your plant, we will need a complete list of input and output data items, broken out separately for each kiln, dryer or furnace. While we typically gather this information during a site visit, any help provided by the customer will speed the quoting process and may lower system costs.Details for all control zones (loops), including combustion zones and airflow control zones, including

Direct temperature measurements not included in the count of control zones

Measurements of pressure, flow, fuel, power, etc., with electrical format (ie, DC volts, 4-20ma, etc.)

Motors, blowers, safety-train indicators, etc.

Switched outputs such as flashing control valves, afterburners, coolmode, alarms, etc.

Count of independent pulsers (for one or more burners)

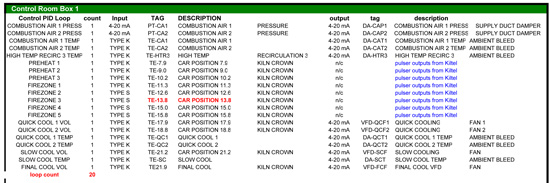

The following table shows a few of the process variables specified for a brick plant tunnel kiln, and illustrates the level of detail required to ensure that the Kiltel system is correctly configured.

Please do not hesitate to contact Kiltel to discuss your requirements.